Dentists / Doctors / Inventors / Medicine / Science

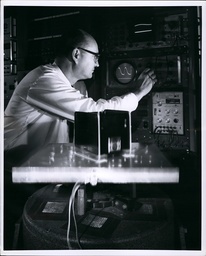

Nov. 11, 1968 - Tiny droplets of solder or other bits of manufacturing debris that might cause early failure of sealed electronic assemblies can be detected easily with a highly sensitive quality control technique developed at the General Electronic Research and Development Center. in this technique, a sea;led is fastened to a vibration table and is shaken. An utrasensitive listening system, detects the sounds of foreign particles - some as small as grains of salt - as they around inside the ''black box''. GE engineers expect that the neew detection technique will have numerous applications on the production lines of manufacturers of military and aircraft electronis, and various electronic and mechanical space components. The technique also should prove useful in the production of other high - quality, ''clean'' assemblies. Here, Max W. Schulz, an acoustics engineer at the Research and Development Center, analyzes a small amplifier for loose particles. (Credit Image: © Keystone Pictures USA/ZUMAPRESS.com)